Table of Contents

Report

The GreenHouse

Author(s):

- Alisson Calderon

- Antonio Martins da Mota

- Christophe Hopchet

- Cristina Grabulosa Olivé

- Mathias Roeper

Acknowledgement

Team 4 would like to thank everyone involved for the completion of this project.

First of all they would like to show great gratitude to ISEP for organizing this EPS and giving them the opportunity to work together with people with different nationalities and backgrounds.

They would also like to acknowledge the supervisors for their help and guidance to a good solution for the project.

Last but not least they want to thank the teachers of ISEP for sharing their expertises on the subjects with them and also helping them write the report.

Glossary

<WRAP box 600px>

| Abbreviation | Description |

|---|---|

| EPAL | European Pallet Association |

| EPS | European Project Semester |

| INPI | Instituto Nacional da Propriedade Industrial |

| ISEP | Instituto Superior de Engenharia do Porto |

| LCA | Lyfe Cycle Analysis |

| LED | Light Emitting Diode |

| NSPE | National Society of Professional Engineers |

| PESTLE | Political, Environmental, Social, Technological, Legal, Economical |

| RACIQ | Responsible, Accountable, Consulted, Informed, Quality |

| SMART | Specific, Measurable, Achievable, Realistic and Timed |

| SWOT | Strengths, Weaknesses, Opportunities, Threats |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

</WRAP>

1 Introduction

1.1 Presentation

This project is developed by Team 4, better known as Team Pingun from the EPS@ISEP in Porto. The team consists of five different people with different nationalities and different educational backgrounds.

In the team there are the following members (Figure 1 from left to right):

- Christophe Hopchet - Electromechanics - Belgium

- Alisson Calderon - Packaging - France

- Mathias Roeper - Environmental Engineering - Germany

- Cristina Grabulosa Olivé - Industrial Design and Product Development - Spain

- António Martins da Mota - Mechanical Engineering - Portugal

The team name, Pingun, is derived from penguin. A penguin is a real group animal and never works or lives alone. Because this spirit is also really important in the team, the penguin was chosen as a mascot. A penguin is also good at keeping its body temperature stable in cold environments. This is something that was important in the development of The GreenHouse.

<WRAP centeralign>

</WRAP>

1.2 Motivation

When the team got to know each other in the first week of the EPS, they felt that every team member had the same objectives and purposes for this semester. They all wanted to learn new interesting things and develop a skill to work together with really diverse people in one team. So, when the team was presented with the different project proposals, they unanimously decided that the greenhouse project would be their number one choice.

The first reason this project was chosen was that every team member directly saw how their knowledge and skills could help bring this project to a good end. This way, every team member could also learn something about the knowledge and skills of the others. Another thing that got them to choose this project was the fact that it had something to do with nature. In the team, every team member likes plants and animals and likes to be active to preserve nature. For example Christophe who's a vegetarian for ecological reasons or Mathias who studies environmental engineering. The last reason that they choose this project was a more practical one. They all agreed that this project could be really workable in the different side courses they would get that semester.

The team was sure that they could bring something new and exciting with this project.

1.3 Problem

Eating good and healthy is a hot topic these days. People are more and more concerned with what they eat and drink. Because of this trend, the demand for fresher and healthier food is bigger than ever. Most of the time global supermarkets don't supply food that's fresh enough for this new generation of foodies. So, if you want this really fresh and healthy food you have two choices: buying it in bio or local market or cultivating it yourself [1].

Often people want to choose for the second option because in that case they are very sure that it is totally fresh and healthy the way they want it. The problem with this option is that most people have an active and busy life, so they don't have time for cultivating this fresh food. This is where The GreenHouse fits in. The team supplies a semi automatic greenhouse where people can grow and cultivate fresh aromatics plants without having the hustle of putting too much time in it.

1.4 Objectives

The team will make a semi automatic greenhouse that is specially built for people who live in apartments or small houses with balconies. The GreenHouse will allow growing and cultivating aromatic plants with as little as possible help of the customer itself.

1.5 Requirements

The project requirements were:

- Design, develop and test a small/medium scale greenhouse. The target user segment and the full set of device requirements are to be defined by the team based on the marketing, sustainability and ethical analyses, as well as on the needs of the client.

- Comply with the following EU Directives:

- Mandatory adoption and use of the International System of Units [7].

- Use open source software and technologies.

- Keep construction costs of the prototype under 150.00 €.

These requirements were stated in the beginning of the project by ISEP. Along the project development, more requirements will be considered.

1.6 Functional Tests

When the prototype was finished some tests were conducted to see if it worked properly and was ready for the commercial market. Here you can find the different kinds of tests that were performed:

- Temperature sensor test:

A hairdryer was used to warm up the sensor. This way the team could see if it gave a signal at the right temperature to the controller board.

- Rain sensor test:

For this test some water was put on the sensor to see if it gave a signal to the controller board.

- Water warning system test:

The water level in the water tank was changed in order to see if the warning led lighted up.

- Motor test:

Inputs were given to the motor to see if it could open and close the summer cover.

- Wick test:

Different wicks were put in water, with toilet paper on top of it. This way it was possible to see which type of wick absorbed the most water.

- Isolation test (winter cover):

The GreenHouse was put in a cold environment to see if the temperature staid hot enough inside.

1.7 Project Planning

Before beginning the project, a list of each task to perform during the project was made. A responsible person was also chosen for each task. The person with the most knowledge on a certain task was allocated to that task. This way the team would be able to accomplish this task at best. Each team member was responsible for one task at a time and with the help of the others, he could carry out this task well and on time. At the end, the team could deliver the product by having validated each task.

All the tasks are grouped together in Table 1 with each responsible person.

<WRAP centeralign>

| Task | Responsible |

|---|---|

| Plan | |

| Allocation task | All |

| Gantt | Alisson, Christophe |

| Research and Development | |

| Target | Cristina |

| Research and choice of the plant | Cristina, Alisson, Mathias |

| Analysis of competitors | Cristina, Alisson |

| Research and choice of resources | Christophe, Cristina |

| Research on components | Christophe, Mathias, Antonio |

| Controlling system code | Christophe |

| Black box diagrams | Mathias |

| Structural draft | Cristina |

| Electronic schematic | Mathias |

| Drawings | Cristina, Antonio |

| Solidworks | Antonio |

| Carboard scale model | Antonio, Cristina, Mathias, Alisson |

| Legal research | Christophe |

| Budget | Cristina |

| Research on materials | Antonio, Mathias |

| Production | |

| Electronics | Christophe, Mathias |

| Mechanics | Antonio |

| Build the structure | Mathias, Antonio |

| Assembly and testing | All |

| Packaging | Alisson |

| Delivery | |

| Report | All |

| Presentation | Cristina |

| Leaflet | Alisson |

| Poster | Cristina |

| Video | Mathias |

| Website | Alisson |

| Wiki | Christophe, Alisson |

| Product | All |

| Instruction manual | Alisson, Mathias, Antonio |

| CD | All |

</WRAP>

</WRAP>

1.8 Report Structure

The report is divided into eight chapters:

- Introduction: In this chapter, there is an introduction of the team behind the project as well as a short description of the project itself with its problem, objectives and requirements.

- State of the Art: This chapter will present the modern technologies and research that already exists on the topic of the project.

- Project Management: Everything regarding the way the team planned and managed the project is included in this chapter. In this chapter the Gantt chart, the task allocation and other managing tools are present.

- Marketing Plan: This chapter consists of all the information on how the team would market the product.

- Eco-efficiency Measures for Sustainability: This chapter states which economical, environmental and social responsibilities where taken into account the development of the product.

- Ethical and Deontological Concerns: The ethical concerns that were taken into consideration for the development of the product were discussed in this chapter.

- Project Development: The chapter about project development outlines how the product was developed and produced.

- Packaging: The chapter on Packaging refers to the way the product would be packaged.

- Conclusions: The conclusion gives a short summary of the project and discusses how this project went for the team and how it influenced every team member for the future.

2 State of the Art

2.1 Introduction

A greenhouse is a structure intended for plants growth with a specific controlled atmosphere (temperature, humidity, light…). It is used to project a faster growth of plants or in some countries where the climate is not appropriate to correspond to the needs of the plants. It also permits to have vegetables and fruits all year long and not just for a season. There are two types of uses: industrial or domestic. Moreover there are a lot of different possibilities to build a greenhouse, and a lot of ways to make it works [8].

This chapter describes the current existing technologies to cultivate plants at home. For each type of cultivation technology, a description of how they work, which type of functionalities they have, and what their specific purpose is presented. After the description of all the different types of cultivation technologies, a comparison of all their functionalities is included to sustain the chosen type for The GreenHouse.

2.2 Existing greenhouses

In this part of the state of the art, the team has been researching the various types of greenhouses and other products related to growing plants to have an idea to which to start the project.

2.2.1 Scientific and touristic greenhouses

Purpose:

The purpose of The New York Botanical Garden shown in Figure 2 is to collect a large variety of plants that come from different continents to study them but also to exhibit them in one place. This way tourists or locals can enjoy the scarcity of plants and schools may visit it for an educational purpose [9].

<WRAP centeralign>

</WRAP>

Structure:

The building is organized with eleven glass pavilions that are all open on the inside. The structure of this house is made with glass and metal. To provide shadow, some parts of the glass are grounded. Each pavilion house has a different group of plants representing various weather conditions found around the globe.

The Conservatory is a grand victorian-style crystal palace made up of eleven interconnected glasshouse galleries. The center piece is a glass dome that features a large collection of the world’s palms under glass. The other ten glasshouse galleries are arranged in pairs on either side of the Palms of the World Gallery, each one displaying a different natural habitat and offering visitors an environmental tour around the world.

Table 2 includes the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| Preserves rare plants | Presence of plants only |

| Allows an educational purpose | No trade in plants |

| Brings a large collection of plants for scientists | Require expensive and expensive labor |

| Long time dedicated to its maintenance |

</WRAP>

</WRAP>

2.2.2 Industrial greenhouses

These allow growing plants massively in order to sell them. This type of greenhouses may be framed into three categories: low technology, medium technology and high technology greenhouses.

2.2.2.1 Low Technology Greenhouse

Purpose:

Use low technology to grow vegetables thus contributing for being sustainable and eco-friendly. For cold winter, Eliot Coleman, a grower specialist in low technology greenhouse production wrote a book titled “Winter Harvest Handbook” explaining how it is possible to grow plants without technology during winter with a cold house [11]. The purpose for Eliot Coleman is to expand the production season using other method than technology.

Structure:

This type of greenhouse has a tunnel or igloo shape with metallic skeleton and plastic cover. They have poor ventilation but their structure is relatively inexpensive and easy to erect.

To protect the vegetables a plastic cover is necessary and it permits to keep the warm in the soil. This double protection also allows relative humidity to increase, protecting plants against frost like shown Figure 3.

To control the plants growth, Eliot Coleman explains the methods and tricks to improve the growth of plants without using technology. These include the construction and maintenance of greenhouses, planting schedules, crop management and harvesting practices [12].

<WRAP centeralign>

</WRAP>

Table 3 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| Sustainable | Sales restricted geographically |

| No pollution | No mass culture |

| Bio food | Only seasonal plants |

</WRAP>

</WRAP>

2.2.2.2 Medium Technology Greenhouse

Purpose:

Almeria is the largest concentration of greenhouses in the world, covering 26 000 hectares. Several tons of greenhouse vegetables and fruits such as tomatoes, peppers, cucumbers and zucchinis are produced annually in Almeria. This is due to imported soils and fully hydroponic systems that drip chemical fertilizers into grow bags. Figure 4 shows the big plantation of greenhouses in this region [14].

<WRAP centeralign>

</WRAP>

Structure:

This type of greenhouse has a tunnel or igloo shape with metallic skeleton and plastic cover.

Technology:

Plants don't touch there soil - they grow from bags filled with oven-puffed grains of white perlite stone. Chemical fertilizers are drip-fed to each plant from a wide, computer-controlled vats

Perlite is made by heating silica (flakes of glass) until it expands (like popcorn). Due to its low density and relatively low price, this substance is used in Almeria. The small nodules hold water well, yet also provide excellent drainage in horticulture. This medium keeps plants more open to air, while still having good water-retention properties, and therefore it makes a good medium for hydroponics [16].

Table 4 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| Large production of fruits and vegetables | By reflecting sunlight back into the atmosphere, the greenhouses are actually cooling the province |

| Pollution of the sea with plastic wastes |

</WRAP>

</WRAP>

2.2.2.3 High Technology Greenhouse

Purpose:

Today the Netherlands has many of the largest greenhouses in the world, some of them so vast that they are able to produce millions of kilos of vegetables every year. One of the largest greenhouse regions is the Westland. Although these greenhouses are capital intensive, they offer a highly productive, environmentally sustainable opportunity for an advanced fresh produce industry [17].

Structure:

The Dutch Venlo greenhouse is the most popular of the greenhouse structures show in Figure 5. Its characteristics are adapted for growers and suppliers.

The Venlo greenhouse has a simple structure. It is composed by a basic steel structure and an aluminium roof system which requires low-maintenance. The truss system inside makes for a broad range of possibilities regarding technical installations and crop suspension. The steel structure is light, yet strong. These structures offer superior crop and environmental performance. High technology structures will have roof ventilation and may also have side wall vents [18].

<WRAP centeralign>

</WRAP>

Technology:

Due to excessive ground production in the Netherlands, groundwater has been polluted, which forced producers to remove their crops from the soil.

New irrigation systems had to be found. The hydroponic system was one solution. This system is based on the growth of the plant shows in Figure 6. Gutters are suspended from the structure of the greenhouse, mineral wool carpets are placed on the gutters as a hydroponic medium. The plants are hydrated by a drip irrigation system where water is collected by the gutter. Excess water with minerals is collected in a drainage tank to eradicate all possible diseases. In many cases, the drained water is treated by a UV sterilizer with enough energy to destroy harmful bacteria and viruses.

<WRAP centeralign>

</WRAP>

The heating of a greenhouse is done by using a central gas boiler. In some cases, heating the greenhouse is done by installing air heaters in the growing areas. These hot air heaters run on either natural gas, petroleum and diesel.

Artificial lighting is used to allow growers to increase their productivity and extend the growing season. Artificial greenhouse lighting is designed to enhance energy efficiency. So greenhouse lighting systems provide a different spectrum than usual light sources and are constantly innovating to optimize their energy efficiency.

Table 5 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| Big varieties of products | Expensive |

| Big production |

</WRAP>

</WRAP>

2.2.3 Domestic greenhouses

Purpose:

Greenhouses in gardens have a medium size, that is to say consumers can't put it inside the house but they can put it in there garden. A large amount of plants can be grown while controlling the atmosphere.

Structure:

Greenhouses in gardens have two types of shades: the first one is tunnel like in Figure 7 and the second one is the same shape and size as a garden shed. The tunnel is made with a wooden or metal structure and covered with transparent plastic. The second shape is also made with a wooden or metal structure and covered with plastic or glass like in Figure 8. They have a door and windows for the aeration. The wooden or metallic parts are the skeleton of the greenhouse. The plastic or glass part covers the structure to keep the warm and let through the light needed for the growth of plants.

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

Watering systems:

The watering can be manually but also automatic like with a fogger or drip irrigation. It depends on the consumer's budget budget and the free time for hobbies. Drip irrigation system allows a continuous irrigation of the greenhouse thanks to a system of pipes to dispose at the feet of your crops. Figure 9 is a structure schematic. The system is controlled by a thermostat that provides the amount depending on the ambient temperature. You must connect the watering system to a water inlet or to a rainwater collector. The amount of water can be adjusted individually by planting.

<WRAP centeralign>

</WRAP>

Control of the temperature:

To isolate the inside, bubble wrap is used. To bring shade the consumer can use a shade net. Finally there exist several types of heating: electric heating, heating oil, fans and heating table with electric heating cable.

Table 6 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| Fresh food | You need a garden with space |

| You can grow your own plants | Plants need maintenance |

| It is expensive |

</WRAP>

</WRAP>

Thanks to this research, the team has a better idea of what a greenhouse is. For the project, the first requirements chosen are to build a domestic greenhouse with an automatic irrigation system. However, the team would like to target a different type of audience than those with a garden, and would like to offer the opportunity for people living in cities to grow their own plants. That is why the research is extended beyond the greenhouses.

2.3 Cultivation possibilities in a small space

2.3.1 Cultivation without technology

Purpose: Indoor allotment is a miniature garden with three pots that the consumer can put inside on the kitchen and grow small plants like aromatic plants. There is no technology so all gardening is done by the consumer as for a real garden. Figure 10 shows the product [24].

<WRAP centeralign>

</WRAP>

Table 7 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| It takes small space | This system need maintenance as for a garden |

| The consumer can grow his own plants | The consumer has only three pots |

| The consumer doesn't need a garden |

</WRAP>

</WRAP>

2.3.2 Cultivation with technology

Purpose:

Aerogarden is a little greenhouse reserved for indoor use in a kitchen. The Aerogarden permits to grow five times faster than to put the vegetables in normal soil. This way the consumer can grow any plant (within the limit of plants proposed by the brand), at any time of the year and without much maintenance. It automatically creates optimal conditions for the plants by turning grow lights on and off to simulate the sun, and reminds the consumer when to add water and nutrients. Figure 11 shows the product [26].

<WRAP centeralign>

</WRAP>

How it works:

It informs the consumer when he has to add water, nutrients and turn on the light. The reservoir provides the root system with an abundant balance of oxygen, water, and nutrients to enable plants to grow five times faster than when grown in soil. Figure 12 shows how it works.

<WRAP centeralign>

</WRAP>

Technology:

The brand propose different kind of products. There are two systems: the first one adds oxygen to the water by circulating the water up through the grow deck and over the seed pods and the roots of the plants. The pods do not have to reach down in the water of the bowl. The second one has an aerator to directly oxygenate the water, and their seed pods are about 8.25 cm long so that they reach down into the water in the bowl, allowing them to draw water up through the grow sponge into the roots of the young plants.

Concerning the lighting system, it provides high performance, energy efficient around 30.00 W LED lighting for plants. This garden tailors the light spectrum to help plants thrive, concentrating daylight white LED lights for fast growth, blue LED lights for bigger yields, and red LED lights for more flowers and fruit. Figure 13 shows the system.

<WRAP centeralign>

</WRAP>

Table 8 contains the advantages and disadvantages of this system.

<WRAP centeralign>

| Advantages | Disadvantages |

|---|---|

| It is easy to use and low maintenance | You can only use AeroGarden accessories and seeds |

| It grows 5 times faster than soil | The product has to be near an outlet |

| You can grow anything including fresh herbs, salad greens, vegetables, flowers, and more | |

| LED lights cost just pennies a day to operate | |

| No need for land to use | |

| No mounting when receiving |

</WRAP>

</WRAP>

2.4 Comparison

After having analyzed some the types of existing greenhouses, the advantages and disadvantages of each are compared to have a clear idea of the type of greenhouse that will be chosen to develop the project like. Table 9 shows a comparison of all the different types of greenhouses.

<WRAP centeralign>

| Type | Target | Technology | Purpose |

|---|---|---|---|

| Scientific and touristic | Schools, Scientists, Tourists | Not specified | Collect a huge variety of plants |

| Industrial | Producer and traders | Low, medium and high technology | Produce in large quantities and throughout the year |

| Domestic | Citizen | Medium and low technology | Grow your own fresh food |

</WRAP>

</WRAP>

2.5 Conclusion

After the research in the state of art, the team decided that The GreenHouse would be a mix between Aerogarden and the domestic greenhouse. It would be a semi automatic greenhouse that can be put on balconies. The first and most important requirement was that it could work in winter and summer in different environments. A specific cover for winter and for summer would be made to provide this use in different environments. It had to be multifunctional. The GreenHouse concentrates on domestic use. It would be made especially for small size aromatic plants. The interaction with the customer should be as little as possible. It would have an automatic irrigation system . The GreenHouse would be powered by batteries or solar energy, this way a socket is not needed nearby.

After the general requirements of The GreenHouse were set it was time to take a look at how the project would be managed and controlled.

3 Project Management

3.1 Introduction

Before starting to develop the product it was important that the whole project got managed. In order to better manage this project, the team made use of management tools. By working together, helping and listening to each other, the management of the project succeeded even if it was the first time that the team worked together.

A project is defined by three things [30]:

- Its carateristic of being unique

- Scope, time, budget

- The stakeholders

To be sure the project would run smooth the team had to define all these characteristics. The team defined these characteristics with the help of different management tools. First, the team began by defining the scope with the help of a WBS (Work Breakdown Structure). After, the team knew the scope they defined every task and put it and a Gantt chart together with the resources. This way they would manage the time aspect of the project. To manage the budget they made a list of all the different costs they needed for the project and saw if it fitted in the budget. For the stakeholders management they first looked at how every stakeholder influenced the different parts of the project. They did this with the help of a RACIQ matrix (Resposible, Accountable, Consulted, Informed, Quality). After this they also looked at how big the interests and power of the different stakeholders on the project were. In this chapter they also defined how they would communicate within this project with every stakeholder or team member. Last but not least they defined some risks that could happen in this project to see if they could minimize them.

3.2 Scope

The scope includes all the objectives of the project and all the actions necessary to achieve it. To define a scope well, the team had to identify the goals, the tasks, the resources, the budget and the timeline of the project. All these parts have been studied by the team and are detailed in the rest of this chapter.

To carry out a project correctly, there first must be a good project scope statement with a purpose, a time and a budget. This allows to target the subject well and to know exactly what is expected. The project scope statement was to develop a semi automatic greenhouse with a budget of 150.00 € (for the prototype) and deliver it for the 18th of June 2017.

To help define the scope, the team made a WBS where the detailed set of deliverables is shown. The WBS permit them to decompose the project scope in simple graphic terms with easy components. At the top the name of the project is stated and below the main components of the project with the list of all the deliverables.

In Figure 14 the WBS of the project is shown.

<WRAP centeralign>

</WRAP>

3.3 Time

The timing of a project is very important to be sure to deliver the product on time. For this project, the supervisors gave the team several deadlines, visible in Table 10, that had to be respected.

<WRAP centeralign>

| Deadline | Tasks |

|---|---|

| 2017-03-06 | Define the Tasks, subtask allocation and Gantt chart of the project and insert them on the wiki |

| 2017-03-13 | Upload the “black box” System Diagrams & Structural Drafts to the wiki |

| 2017-03-27 | Upload the detailed System Schematics & Structural Drawings to the wiki and finish the cardboard scale model of the structure |

| 2017-04-03 | Upload the List of Materials (what & quantity) to the wiki |

| 2017-04-09 | Upload the Interim Report and Presentation to the wiki |

| 2017-04-20 | Interim Presentation, Discussion and Peer, Teacher and Supervisor Feedbacks |

| 2017-04-24 | Complete the List of Materials (local providers & price - including VAT and transportation) to the wiki |

| 2017-05-02 | Upload refined Interim Report (based on Teacher & Supervisor Feedbacks) |

| 2017-06-05 | Upload the Functional Tests' Results to the wiki |

| 2017-06-18 | Upload the Final Report, Presentation, Video, Paper, Poster and Manual |

| 2017-06-22 | Final presentation |

| 2017-06-26 | Final report with correction, CD and print the report |

</WRAP>

</WRAP>

With these deadlines and the table of the tasks defined, the team used them to make a timeline of the project. This way there was an overview on the planification. Thanks to this timeline, it was possible to see what were the past tasks and what were the next steps of the project. To make this timeline the management tool Gantt chart was used, which permit the team to have a lot of information for each task, such as the responsible, the duration, the milestone and the cost. In Figure 15 the Gantt chart for this project is shown.

<WRAP centeralign>

</WRAP>

3.4 Cost

Cost is one of the three constraints in a project together with time and scope. Analysing the cost helps to identify each of the expenses within the project. This way it is ensured that expenses are approved before purchasing and the overall cost of the project is controlled. In the project there are two types of costs: work resources and materials.

Work resources refer to the human resources required during the project that have to be payed according to the time. For the project, the team members were not payed because it was within the framework of their studies. Nevertheless it is interesting to put them selfs in a context of start up. Table 11 shows the salary for the team regarding the four months of the project. This table is made thanks to Project Management Software.

<WRAP centeralign>

| Resources | Work (h) | Rate (€/h) | Cost (€) |

|---|---|---|---|

| Alisson | 417.20 | 10.00 | 4172.00 |

| Antonio | 343.60 | 10.00 | 3436.00 |

| Christophe | 427.28 | 10.00 | 4272.80 |

| Cristina | 342.80 | 10.00 | 3428.00 |

| Mathias | 374.40 | 10.00 | 3744.00 |

</WRAP>

</WRAP>

The second type of costs is the materials. For each unique project, there is a unique budget. For this project the budget was 150.00 € to develop the prototype. This budget was imposed by the supervisors and included only costs related to the construction of the prototype. Table 12 shows the details of the materials that were used to build the prototype.

<WRAP centeralign>

| Material / Component | Type / Size | Quantity | Price (€) |

|---|---|---|---|

| General structure | |||

| Wood tubes | Ripa sem aplainar (13 mm x 25 mm x 2400 mm) | 1 | 1.00 |

| Wood panel | Painel de contraplacado (1200 mm x 600 mm x 5 mm) | 1 | 4.99 |

| Isolation | Placa de isolamento (0.5 m2) | 1 | 2.55 |

| Transparent foil | Plástico de proteção transparante (5000 mm x 2000 mm) | 1 | 4.99 |

| Aluminium tubes | Perfil de alumínio plano (15 mm x 2 mm x 2500 mm) | 1 | 2.99 |

| Steel tubes | Perfil tubo aço quadrado (12 mm x 12 mm x 1000 mm) | 4 | 15.96 |

| Screws | 3.5 mm x 50 mm | 1 | 1.50 |

| Screws | 3.5 mm x 35 mm | 1 | 1.59 |

| Glue | Cola para mandeira (250 g) | 1 | 2.39 |

| Paint | Spray Multisuperficies (0,4 l) | 1 | 9.99 |

| Wick | (4 mm) | 1 | 1.99 |

| Electronical components | |||

| Temperature sensor | DS18B20 | 1 | 6.70 |

| Rain sensor | / | 1 | 6.13 |

| Micro switch | / | 2 | 2.22 |

| Float switch | / | 1 | 4.99 |

| Push button | / | 1 | 2.90 |

| Switch | / | 1 | 0.90 |

| Wire | Jumper wire | 1 | 3.49 |

| Control system | Arduino Uno - R3 | 1 | 22.99 |

| Geared DC motor | MOT02034 | 1 | 14.45 |

| Batteries | 8x Alkaline AA batteries | 1 | 3.00 |

| Battery holder | Holder 5 AA batteries | 1 | 2.90 |

| Motor controller | H-bridge | 1 | 2.46 |

| Clip for LED | / | 3 | 0.48 |

| Green LED | / | 1 | 0.16 |

| Red LED | / | 1 | 0.16 |

| Yellow LED | / | 1 | 0.16 |

| Resistors | / | 10 | 0.90 |

| Transportation | |||

| Boxelectronica | 4.60 | ||

| Diverta | 4.60 | ||

| Onlybatteries | 4.60 | ||

| Total price | 138.73 | ||

</WRAP>

</WRAP>

3.5 Quality

Product quality is really important to attract and retain customers. If the quality is bad, the product will have a bad reputation that will lead to a decline in sales, but also a bad reputation for the brand. The GreenHouse didn't have a place in the market, the company had to prove itself, there was no right to make mistakes. For this reason, the quality of The GreenHouse had to be controlled.

3.5.1 Product Quality

To have a good final product, there must be a good quality of raw materials. For this, suppliers with a good reputation had to bee chosen. When receiving each component the quality and functioning had to be controlled before using them. Once the product was assembled, the team had to test it to make sure it worked well and was durable.

3.5.2 Work Quality

The quality of the raw materials was good, but if the quality of the work was not correct then the quality of the final product would have been bad. Therefore the components had to be handled with care and the assembly had to be made by a certain quality. Moreover, the well being of the team was important. If the assembly of the product happened in a bad atmosphere then this would have repercussions on the quality. Finally, to assemble and test the product, a quality environment was needed.

3.5.3 Service Quality

After selling The GreenHouse, it is important to listen to customers. All reviews are good to improve The GreenHouse. In addition, a good relationship has to be kept with them to keep them loyal and ensure a good after sales service if one of the products does not work properly.

3.6 People

A project is composed of many tasks in various fields which requires several actors with different specialties to be able to manage the project properly. The team is composed of five students with different backgrounds. Thanks to that, it was easier to allocate the tasks. This way each person could bring their skill and knowledge on a part of the project. However, an outside eye was always needed to bring constructive criticism and improve the project. This is why it is important to work as a team and not alone in your field. Moreover, if the person could not manage an area he does not know, he had to be able to learn and discover something that he was not accustomed to seeing.

Finally, to work with other persons on a project allows to divide the work to be more efficient but also in case of absence or disease, the work could be done by the other. In Table 13, each task was distributed among several members with different roles. The team decided to use the RACIQ matrix because it is an appropriate tool for assigning roles.

A RACIQ matrix is composed by the following roles:

- Responsible: who is assigned to do the work.

- Accountable: who makes the final decision.

- Consulted: who can help for something precisely.

- Informed: who must be informed if a decision has been taken.

- Quality: who does the quality test.

<WRAP centeralign>

| Tasks | Alisson | Antonio | Christophe | Cristina | Mathias | Supervisors | Teachers |

|---|---|---|---|---|---|---|---|

| Gantt | R | C/I | A | C/I | C/I | I | I |

| Research on components | I | C | A | I | R | C | I |

| Research on materials | C/I | A | C/I | C/I | R | C | I |

| Black box diagrams | I | C | A | I | R | C | I |

| Structural draft | I | C | I | A | R | C | I |

| Electronic schematic | I | C | R | I | A | C | I |

| Solidworks | A | R | I | I | C | I | I |

| Carboard scale model | C | R | I | C | A | I | I |

| Programming | I | C | R/Q | I | A/Q | C | I |

| Packaging | R | C | I | A | I | C | I |

| Build the structure | C/I | A/Q | C/I | C/I | R/Q | C | I |

| Testing | I | A/Q | R/Q | I | C | C | I |

| Report | R | R | R | R | R | C | I |

| Leaflet | R | I | I | A | I | I | I |

| Poster | A | I | I | R | I | I | I |

| Website | R | I | C | A | I | I | I |

| Wiki | A | C/I | R | C/I | C/I | I | I |

| Instruction manual | R | R | C | I | A | C | I |

</WRAP>

</WRAP>

3.7 Communication

Communication is a key factor when working in a team. Certainly when the team members have never worked together. This is because nobody knows what to expect from the other. To keep good communication the team tried to do meetings at school almost everyday. This way they could inform each other on what everyone had done or was working on. Important decisions and discussions were done in these meetings. When there were new tasks that rise they were also divided in these meetings. Every week there also was a meeting with the supervisors so the team could keep them up to date on how the project was developing. In these meetings the supervisors also guided them to finish this project in a positive way.

When the team was not together they communicated by Whatsapp. This way they could quickly ask things to one another or make little decisions. The sharing of content was done by means of Dropbox. This Dropbox consisted of different maps that refer to the different parts of the project. This way everyone could find everything they need there.

In Table 14 all the communication actions are grouped and detailed.

<WRAP centeralign>

| What | Why | Who | When | To Whom |

|---|---|---|---|---|

| Weekly meeting with supervisors | To see the progress in the project, give a feedback about the wiki and help us | The supervisors | Every thursday | The team |

| Weekly meeting with the team | To know who works on what and who should do what | The team | Every thursday | The team |

| Meeting with our coordinateur | To help us with techincal questions | Abel Duarte | 21-03-17 | The team |

| Deliverables | To show the progress of the project to the supervisors and to deliver the final product and all associated documents | The team | 3.3 Time | The supervisors |

</WRAP>

</WRAP>

3.8 Risk

Analyzing the risks in a project permits to anticipate threats that can be encountered during the project. This way it is easy to see what might be done to minimize these threats. Anticipating allows to react faster and thus avoid wasting too much time during the project to solve the problems.

For the project the nature of potential threats were listed first:

- Human-caused hazards: absence of one member of the team, workplace accident.

- Natural hazards: bad or good weather during the testing period.

- Material hazards: insulation not efficient enough, the quality of the material is not as expected, breakdown of equipment during testing, the support does not fit correctly on the balcony.

- Technological hazards: failure of the system with the arduino.

- Management hazards: failure to meet deadlines, budget not respected.

Once the threats had been identified, they were grouped into Table 15 to analyze them.

<WRAP centeralign>

| Description | Cause | Effect | Trigger | Response | Impact | Probability | Rank |

|---|---|---|---|---|---|---|---|

| Failure to meet deadlines | Unforeseen events | Delay in the project | Expected time for each task too short | Mitigate: analyse all the stapes and risk for each and allow more time for each task | High-3 | High-3 | 9 |

| Absence of a member | Diseases or personal issue | Bad condition of work for the team | Team member feels bad | Accept: divide the work of the person | Medium-2 | High-3 | 6 |

| Test not conclusive | Bad weather | Delay in the project | Bad weather forecast | Mitigate: allow for a long period of testing | High-3 | Medium-2 | 6 |

| Temperature not controlled | Isolation not efficient enough | Bad condition for plants | Bad choice of material | Accept: improve the isolation with more matter | High-3 | Medium-2 | 6 |

| Bad material | Quality is not as expected | Bad quality of the final product | Bad choice of material | Mitigate: check the quality before | High-3 | Medium-2 | 6 |

| Failure of the system | Electronics failure | Delay in the project | Bad programming | Mitigate: allow time for testing | High-3 | Medium-2 | 6 |

| Budget not respected | Changes of material | Budget increase | Bad quality of material | Mitigate: provide for a back-up budget | Medium-2 | Medium-2 | 4 |

| Breakdown of equipment during testing | Using in improper way | Delay in the project and budget increase | Lack of knowledge and bad concentration | Accept: be careful when handling materials | High-3 | Low-1 | 3 |

| Balcony's issue | Support not adapted | Delay in the project | We did not look at all types of balconies | Mitigate: provide adaptable hooks | High-3 | Low-1 | 3 |

| Workplace accident | During tests with scissors or others tools | Bad condition of work for the team | Lack of knowledge and bad concentration | Accept: bring more help to the person | Medium-2 | Low-1 | 2 |

</WRAP>

</WRAP>

At the end of the project, the team faced the following risks and found a solution for each:

- Wrong material

Why? Material provided by the school and not exactly what expected by the team

Solution: Adapt the prototype with the new material

- Missing team member

Why? Disease or personal issue

Solution: Provide a support person for each task

- Budget not respected

Why? The team wanted a big product

Solution: Reduce the size of the prototype

3.9 Procurement

Procurement is the part of the project where all the actions concerning the materials and the suppliers are planned. As The GreenHouse contains different parts, different suppliers had to be found and attention to the quality/price ratio had to be payed. Furthermore, the budget was limited so the team had to identify which parts were very important and needed a very good quality.

To meet the budget, a list of all the materials had to be made first. Then the team had to search Portuguese suppliers for these materials and components. Using local suppliers permits to reduce shipping costs and also the shipping time. This allowed to invest in better quality.

After receiving the different materials, the team had to check its quality to ensure that it was the expected one and that this didn't affect the quality of the final product.

3.10 Stakeholders Management

Stakeholders management permits to control all the relationships in the project. Stakeholders are persons who are involved in the project directly or indirectly. Every stakeholder has a different kind of interest and power on the project. The different kind of interests and power are the following:

- High power and high interest

- High power and low interest

- Low power and high interest

- Low power and low interest

For the stakeholder analysis there are three steps: list all the stakeholders, identify the information for each and identify the impact or support for each. For the project, Table 16 was made to easily view this analysis.

<WRAP centeralign>

| Stakeholder | Roles | Expectations | Power | Interest |

|---|---|---|---|---|

| Team members | Creators of the project | Develop the project successfully | High | High |

| Team supervisor | Help us with the project | Successful project | High | High |

| Coordinators | Approve the project | Learn how to develop a team project | High | High |

| Teachers | Give the necessary knowledge | Apply the notions seen in lessons to the report | Low | High |

| Suppliers | Provide equipment | Sell supplies | High | Medium |

| ISEP | Gives a budget and provides the workspace | Deliver a project | High | Low |

</WRAP>

</WRAP>

3.11 Conclusion

Because of this project management the team was able to take control of the project. The different tools in this chapter were used as a base for every decision or task that had to be done. If new tasks would rise the team would be able to plan them well, to be sure other tasks weren't affected by the new ones. When new components or materials had to be added, the team had to take a look at the quality and budget management to see if it fitted in the project. With the risk analysis the team was able to minimize these risks and anticipate on them. For important decisions they could take a look at how every stakeholder should be involved in this decision and how they had to communicate this decisions. This way the project stayed structured and didn't lose its direction to the end product.

After the management of the project it was time to start with the marketing plan and take a look at how the product would be sold. All the research on the marketing can be found in the next chapter.

4 Marketing Plan

4.1 Introduction

Marketing is an essential part in a company. The success of the brand depends on the marketing expertise, because its goal is to respond to the customer’s needs. The first objective is to attract the customers with the product and then to make them loyal. This way marketing doesn't only allow to sell the product but also to make profit. Different tools are used in this chapter to analyse the marketing of The GreenHouse, like Marketing mix, SWOT (Strenghts, Weaknesses, Opportunities, Threats) and SMART Objectives (Specific, Measurable, Achievable, Realistic, Timed) .

The team started by doing a market analysis and looking at the kind of macro and micro environment the product would be in. After this they looked at which factors were going to influence the marketing objectives. This was done by making a SWOT analysis. When the factors that influenced the marketing objectives were known, it was time to define these objectives. These objectives would be defined by the rules of SMART. The next step after the objectives was segmentation. In this part of the marketing plan an overview of the different kinds of consumers were made. After the team knew which kind of consumer was best for the product, it was time to see where the product could be positioned in the market and how the product would be marketed. They team took a look at the four p's of marketing mix: Price, Product, Promotion and Place to define the final marketing plan. Off course it was also important to see if the marketing strategy and plan fitted in a certain budget. All of these research on the marketing plan can be found in this chapter.

4.2 Market Analysis

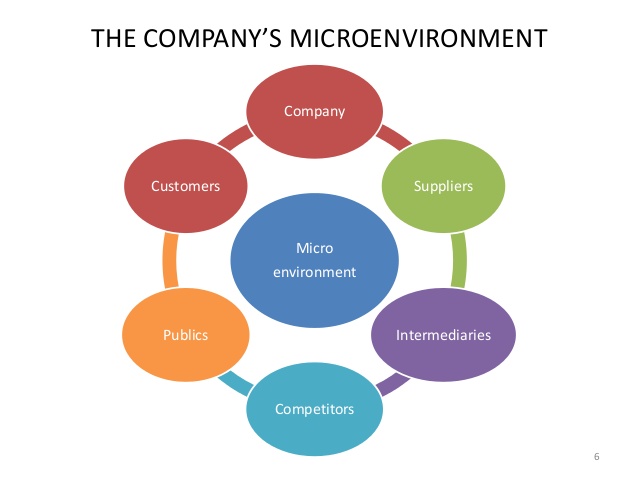

In this chapter influences of the macro and micro environment, on the marketing plan of The GreenHouse, will be stated. Macro environment defines the general environment within which the company is involved. The factors are political, economic, social, technological, environmental and legal. Micro environment permits to analyse the company itself. It groups six factors: suppliers, customers, company, intermediaries, publics and competitors.

4.2.1 Macro Environment

For the analysis of the macro environment the team used a tool called PESTLE (Political, Environmental, Social, Technological, Legal, Economical). PESTLE analysis different outside factors that influences the marketing of a product. Figure 16 shows the different factors that are taken into account for the PESTLE analysis.

<WRAP centeralign>

</WRAP>

4.2.1.1 Political & Legal

Politically seen, the different legislations that are in charge now and in the future, have to be taken into account. Although a lot of countries still have pretty conservative political systems, the younger generation of people vote more liberal. So there is a trend coming that political systems all over the world will become more liberal, open and environmental friendly.

The legal part of the macro environment in the market analysis is pretty dependent on the political system. Because if a certain type of political system is in charge, the laws will probably change to their thoughts. So with the political trend described above the laws about domestic rules and others will also change in a more open and liberal way. Regarding The GreenHouse, the team had to be careful with rules concerning the suspensions on balconies.

4.2.1.2 Environmental

The environment is a topic more and more evoked because of the global warming. Scientists state that if people don't do anything now, consequences will be irreversible. It is why many countries have come together to create the 21th Conference of the Parties (COP21). The goal of this organisation is to decrease gas emissions to 70 % by 2050. The project was in line with this objective because the team used renewable resources like rain water [32].

With this objective of preserving the planet, people try more and more to be eco-responsible citizen but also to have an healthier life. People want products that are made in a sustainable way and they even want to pay more for it. They want products that are produced with the following things in thought:

- Products and packaging have to be designed to be safe and ecologically throughout their life cycle.

- Wastes and ecologically incompatible byproducts have to be reduced, eliminated or recycled.

- Chemical substances or physical agents and conditions that present hazards to human health or the environment should be eliminated.

- Energy and materials have to be conserved, and the forms of energy and materials used have to be most appropriate for the desired ends.

- The security and well-being of all employees has to be a priority, as is the continuous development of their talents and capacities.

4.2.1.3 Social

From a social perspective eating healthy is a hot topic these days. Especially in the group of the millennials. People are searching for healthier and fresher food. We see this in trends like the paleo diet or veganism that are rising in numbers. In Figure 17 the expected change in eating habits, in the next year, are shown by age. It is clear that people are very busy with healthy food [33].

<WRAP centeralign>

</WRAP>

According to the Food and Agriculture Organization of United Nations data, the vegetable supply (excluding potatoes and pulses) in Europe has increased over the last four decades. In 2006, one in five Europeans reported having changed their diet over the last year. Of these, more than half indicated that they had increased their fruit and vegetable intake [35].

A majority of European citizens associate a healthy diet with fruit and vegetable consumption. The idea of growing one's own food continues to grow. In cities people want to have the luxury of having a vegetable garden. Furthermore, it improves the condition of the air. We can see many associative gardens developing, like on roofs. With this project, another solution was proposed: grow your own vegetables on your balcony!

Furthermore, people have a really busy life in cities and they don't want to spend time gardening aromatic plants. When they come back home, people want to enjoy their free time with their family, unwind, relax and forget all constraints. With the semi-automatic system, this project met these requirements.

4.2.1.4 Technological

In terms of technology, The GreenHouse used eco-friendly technology. Sensors (rain, temperature) were used to protect the plants from the rain and the sun and certify the customer operational growth without many manipulations.

4.2.1.6 Economical

In this case the choice of renewable energy in the company can be seen as a green economy. An activity is considered like a “green activity” if it is less polluting, it uses less energy and it concerns the protection of the environment. Eco activities generate many businesses. Governments promote and support green energy development, so this is the perfect period to develop a project in line with sustainable development. Figure 18 shows the different growths of the use of renewable energy. The solar sector is in the first rank of the sustainable energy investment in the world in 2014 according to Eurostat [36].

<WRAP centeralign>

</WRAP>

4.2.2 Micro Environment

Next to the macro environment, the micro environment also had to be analyzed in the market analysis. Figure 19 shows the different factors of the micro environment.

<WRAP centeralign>

</WRAP>

4.2.2.1 Suppliers

Using local suppliers was a budgetary as well as ethical choice. By choosing local suppliers the team was able to maintain a stable economy in the region and avoid all import-related costs. Furthermore it's easier to maintain a partnership with local suppliers because of the proximity.

For The GreenHouse wood, cork, electronics components and plastics were needed. For the production of The GreenHouse, two suppliers for each category, to allow competition between them, were searched. This way the best prices were gotten, but also a rescue provider was available.

4.2.2.2 Intermediaries

Intermediaries can be usefull to expand the sales sector, reach more consumers and promote the product. Customers are important for that but also social networks, advertising companies, local radio and cinema.

4.2.2.3 Competitors

The analysis of the competitors was really important because a value, that our competitors didn't have, had to be found in the product. Furthermore, competitors failures are a way to learn and try to avoid them. For the project differents kind of competitors were found: direct and indirect. Table 17 shows a list of the competitors for The GreenHouse.

<WRAP centeralign>

| Types | Descriptions | Pictures |

|---|---|---|

| Direct | ||

| AeroGarden | They propose an automatic greenhouse with artificial ligth to grow plants quiclky. Their greenhouse works with a power supply and water. The consumer can only growth six plants at the same time and is obliged to buy the specific pre-seeded grow pots to use the greenhouse. |  [39] [39] |

| Indirect | ||

| Supermarket: Continente, Pingo Doce, Jumbo | They sell vegetables and aromatic plants but the quality and the freshness are not so good. However, it remains cheap. |  [40] [40] |

| Biomarket: Cantinho das Aromaticas | They sell vegetables and aromatic plants of good quality but it's a little bit expensive. |  [41] [41] |

| Small kitchen garden: Indoor Allotment | They offer fresh food and homemade but they require maintenance and plants take time to grow. |  [42] [42] |

</WRAP>

</WRAP>

4.2.2.4 Publics

The public targeted by The GreenHouse were people who want to eat healthy and homemade food but don't have time to garden. So the team proposed fresh food, which grows fast and which does not require so much maintenance as a garden. Furthermore, the target public doesn't have gardens and live in flats or small houses so with the product, they can have a little piece of garden with enough space to grow some plants.

4.2.2.5 Customers

Customers are also an important part of the marketing because the product is sold to them. Convincing them that The GreenHouse is worth investing is an important task. Customers attract more consumers. This is, if the company trusts in customers and if customers trust in the product, consumers will trust too.

The type of customers the team targeted are flowershops and trendy eco-shop. Flowershops are adapted to the product because people can buy, with The GreenHouse, seeds and compost. Furthermore, a sales assitant can help the consumer to understand how The GreeHouse works and what kind of plants are suitable to grow.

Trendy eco-shop are also adapted to attract another kind of consumer: those who want trendy objects. These shops can seduce them with a strategy of selling a new concept with an eco-friendly aspect.

4.2.2.6 Company

For this project, we didn't have a company but a team of five students with different nationalities and backgrounds. Everybody could bring something with his or her skills and knowledges. Cristina studies industrial design and product development so she could manage the design of The GreenHouse and could have a perfectionist eye on the production. Antonio studies mechanical engineering so he could manage the mechenical part and the modelling of The GreenHouse. Christophe studies electronical engineering and could be in charge of the electronical part and the plannification of the project. Mathias studies environmental engineering and could be in charge of the environmental, sustainability and materials part. Finally, Alisson studies packaging engineering so she could manage the planification of the project, the marketing part and the packaging part. The nationalities could also help studying various markets and bring cultural knowledge.

4.3 SWOT Analysis

With a SWOT analysis it was possible for the team to see what factors (internal and external) were favorable and unfavorable for achieving the objective. SWOT stands for strengths, weaknesses, opportunities, and threats. The strengths and weaknesses discuss the internal factors while the opportunities and threats discuss the external factors. Figure 20 shows the SWOT analysis for this project. When the team looked at the different factors they concluded that the objective was attainable.

<WRAP centeralign>

</WRAP>

4.4 Strategic Objectives

For a good marketing plan it's really important to know where you are going. Because of this objectives for the next 5-10 years should be described. A good objective is made by the rules of SMART.

Here you can find the objectives for The GreenHouse for the next 5 years:

- Ameliorate the model.

- Find better and permanent suppliers to reduce production costs.

- Do volunteering and charible donations to get connected with the customer.

- Make a platform for feedback of all stakeholders.

- Develop a repair platform.

- Extend the market of the product in five more countries in Europe.

- Develop an app that will notify and inform the customer on the status of The GreenHouse.

4.5 Segmentation

The segmentation in marketing consists of dividing the population in homogeneous groups to fulfil the needs of each group in a more effective way. A good segmentation must be operational and avoid inappropriate choices. Any segmentation criteria must have the following characteristics:

- Measurable: size, purchasing power, and profiles of segments can be measured.

- Accessible: segments can be effectively.

- Reached and served.

- Substantial: segments are large or profitable enough to serve.

- Differential: segments are conceptually distinguishable and respond differently to different marketing mix elements and programs.

- Actionable: effective programs can be designed for attracting and serving the segments.

Four criteria of segmentation were analyzed: geographic, demographic, psychographic and behavioral.

4.5.1 Geographic Segmentation

For the launch of the product it was chosen to target Portugal first. Due to the climate, there are very hot summers that burns plants and very cold winters. After Portugal, The GreenHouse will be sold in other countries that are experiencing the same problems.

The geographic target is in living cities, because The GreenHouse allows people, living in apartments, to cultivate their own aromatic plants. In rural areas, most people have gardens so it is more difficult to attract them. In addition, to achieve an optimal performance of The GreenHouse the aim is for sunny cities.

4.5.2 Demographic, Psychographic and Behavioral Segmentation

With all the scandals about food and brands nowadays, people are losing confidence in supermarkets, especially in big companies. Currently consumers want to know the origin of the food, how it was made, how it was manufactured and under what conditions it has been produced. Therefore, a new trend has begun with the emergence of the organic market, the desire to buy premises and above all the desire to make homemade food. Faced with this movement, The GeenHouse fits perfectly into the market.

For the segmentation, the team decided to focus especially on the age of the public as well as in their diverse needs, such as economical possibilities, aspirations and free-time activities. Not all publics can be attracted by the product. Because of that, a distinction of three different population groups were made: children, young and active people and elderly people. Figure 21 shows these different population groups.

<WRAP centeralign>

</WRAP>

To define in which group to focus the product it was necessary to take in consideration the distinctive characteristics and requirements of each of them as well as the advantages and disadvantages that they present in relation to the product.

The team distinguished three different target groups with different ranges of age inside each: children (from 0 to 12 years old), young active people (from 13 to 50 years old) and mature people (from 51 to +75 years old). Figure 22 shows the different subgroup of ages in each target group.

<WRAP centeralign>

</WRAP>

- Children (0 to 12 y.o.):

Inside this market sector there is distinguished in two different subgroups: babies and kids. Babies are these people from 0 to 3 years old and kids are the people from 3 to 12 years old. Babies and kids are very curious and full of energy that they use in their desire to learn and try all kind of new things. However, they are also innocent and they are susceptible to suffer from accidents or getting injured easily. Most of the population of this sector can present difficulties in handling complicated technologies even though they learn fast and they are open to accept changes easily. The devices for this population groups require high reliability equipments and devices designed especially for their own security. They love to play and discover new things and giving them the opportunity and the responsibility of taking care from plants could be an effective way to improve their own self-realization.

- Young & active people (13 to 50 y.o.):

This market sector comprises a very wide range of population and for this reason it is divided in three age groups: adolescents from 13 to 17 years old, youths from 18 to 30 years old and adults from 31 to 50 years old. In this age groups, there is very active people who spend many hours away home studying, working or with both activities. Youths and adults have clear ideas of what they like and what their priorities are while adolescents are still discovering their own preferences and stablishing their futures. Adolescents appreciate their free time and they don’t like wasting time in meaningless activities so they prefer to use their brief free time in playful activities. With youths and adults, the problem is always with the free time: working and studying requires a lot of hour per day and they need to use their free time in a reasonable way because they have busy lives. This type of people prefers having quality products but without effort. They don’t conform to everything and they handle very well the modern technologies because they were born with them. This sector of population is very open to new things and tolerates the changes well.

- Mature people (51 to +65 y.o.):

This market sector includes two age subgroups: middle age people from 51 to 65 years old and elderly people of + 65 years old. This group of people include the last years of work and the retirement years. They are people who usually do more relaxed activities and they have more free time than young and active people. Middle age people are in their last working years so they still have active lives but they have less energy in doing physical activities. Elderly people have already stopped working and they want to enjoy their lives but they can have limitations of mobility and some kinds of age illnesses.

This sector of the population is more related to nature and old customs and know the fact that for good things you must have patience. They like quality products and know that they have a cost. They are also people who value less objects and more experiences and have come to a time when they value comfort above all things as they have much experience in life.

On the one hand, we have children that can’t cook and they prefer more manual products with less automation and on the other hand elderly people who are more limited in their movements so a manual product can be difficult to handle for them. Both groups are not used to advanced technologies. For the product, the best target is the group of young people because of their needs and lifestyle that fits more with it. Young people are more and more concerned by environmental issues and they want high quality food. They really want to act for our planet and follow the ecological trend that the proposed product allows them to follow: a semi automatic greenhouse that fits with their habits.

4.5.3 Target group

After analyzing the pros and the cons of every group the team has extracted different conclusions of the best choice whom to focus the product.

First, children are too young and unconscious to use a product designed to help in growing plants for cooking. They could grow plants for fun and to get self-realization but the team decided that the disadvantages of having to design it in a safe way, with small size and weight and with an esthetic that attracts children are requirements that need too much research and budget.

About young and active people, this is an attractive target because it includes people that is studying and people that is working and they already have purchasing power to buy the product. This target group includes busy people that appreciates to eat good and healthy but, at the same time, they don’t have time to spend in growing plants and taking care of them. Young people is concerned about by environmental issues and want to act for our planet and follow the ecological trend that the proposed product allows them to follow: a semi-automatic greenhouse that fits with their habits.

About mature people, they are more patience and aware of the need of putting effort to achieve things and they can wait or pay more for an excellent quality result. They have lived different life steps and they have experience in many fields. Technology is not an strange thing but maybe they need more time to get used to some changes or improvements.

In conclusion, the best target group is people from around 25 to 65 years old because it includes the youths that just left their parents houses and are starting their own way in life following an environmental friendly lifestyle and caring about nature and the adults and middle aged people, that are in their last working years, and that they have purchasing power and a clear idea what to use their free time in. It is a very wide range of age group with different perspectives about life and occupations but what they all share is the desire of using fresh products and being sustainable at the same time of trying to do things by themselves and having their free time to develop other activities that they consider more important than taking care of their plants. This group of people is very exigent in quality and they want to spend time, money and effort when it’s necessary, otherwise, they won’t feel comfortable.

The GreenHouse can be a good ally in this target group people’s life so they can be interested in buying it and using it to raise their life quality and forgetting about activities that they can avoid but not refusing to eat healthy and excellent quality food.

In Figure23 is detailed the target group selected that fits more with the product.

<WRAP centeralign>

</WRAP>

4.6 Strategy/Positioning

Positioning the company strategically is crucial to focus on a consumer and create a positive perception of it. The ideas promoted by the company must be highlighted in order to try to stay ahead of the competitors. If you offer a more innovative product and service, you should be able to offer a good perception of it.

In relation to Figure 24, the company has been positioned in the position that has been considered most appropriate in relation to competition. Significant weight has been given to the sustainability and simplicity of the product in addition to its energy efficiency. One of the main objectives of the product is to make the most of all possible natural energies, and at the same time, to be practical and useful for the user by offering a service that the competition cannot, or does not, offer.

<WRAP centeralign>

</WRAP>

The distinctive feature, besides an attractive design, is the fact of designing a sustainable product from its production to its recycling, besides being a product that facilitates the life of the user. In relation to other products of the competition, The GreenHouse will have a higher price since it incorporates technology that others do not include. Furthermore, it is a product that works in a different way in winter than in summer and this is a very strong advantage in a country where the weather changes completely during the year. The rationale is that the type of people who want to buy this product can grow their own plants in an optimal way and invest a little more money for a top quality, environmentally friendly and reliable result.

A very important factor was to know how to communicate the value of the product in an appropriate way in the adequate channels so that the message reaches the right receivers and not waste resources without reward. The key points to focus the positioning are:

- Information about the features of the positive fashion product

- The choice of how, where and to what approach the marketing strategy will be

4.7 Adapted Marketing-Mix

The marketing mix is a tool used in the marketing plan to promote the product in the right place, with a fair price and at the right moment. Therefore marketing mix is often associated with 4 P’s: Price, Product, Promotion and Place. Philip Kotler and Gary Armstrong (a well-known marketing professor) wrote a good definition for Marketing Mix in his book: “The Principles of Marketing” which is “The marketing mix is… The set of controllable tactical marketing tools – product, price, place, and promotion – that the firm blends to produce the response it wants in the target market.” [43].

4.7.1 Product

The product is a good or a service that a company creates to satisfy a need of a specific group of consumers. To avoid the decline of the product and the brand, the marketer must constantly think about the product's improvement to rebuild sales.

The characteristics of the product must give a value that the consumer can appreciate. The product is being developed is a small domestic greenhouse for outdoor use and its main objective is to grow aromatic herbs in good condition throughout the year, regardless of the climate conditions. The purpose of this product is to make the user feel that he is cultivating his own food in a sustainable way since he stops consuming treated and poor quality herbs to season his meals with plants of the best quality and grown in his own home throughout the year. In this way, the user will no longer have to be careful to take care of his plants all the time since the product will do it in a semi automated way. Consumers will no longer have an excuse not to prepare delicious recipes at their leisure with the best herbs.

There are many types of greenhouses in the market today but most require a lot of space and daily care for plants. The GreenHouse has the aim of taking care of the plants and to offer their maximum potential all the time. In addition, The GreenHouse will also collect water from the rain, so there will be very few occasions when the user will have to refill the water tank: only in extreme situations. It is a semi automatic product where the user has a slight interaction with the product but at the same time offers a tranquility and minimal care.

During the summer the consumer just should be aware of the level of water from the water tank because The GreenHouse will protect the plants from the sun and possible rain thanks to its sensors. During the winter, a transparent fixed cover will be enough to protect the plants and provide them with the perfect atmosphere to grow and live. Concerning the identity of the product, that has been explained in the part 8.3.1 Identity.

To improve the product, it is possible to extend the brand with accessories such as pots, seeds or extra covers that give an extra functionality to the product.

4.7.2 Price

The price is the sum against which the consumer must exchange the product in order to benefit from it. When choosing the price, the team had to think about two things: the amount for which the consumer is willing to pay for a product of this type and the amount that the company needs to earn to have profits and survive. If a price that is too low was chosen, the consumer would think that the product would be of poor quality and the company wouldn't be able to make a profit. If the price was too high, there was risk that the consumer didn't buy it and preferred the competitors.

Furthermore, the team had to think in which way the consumer has to pay the product. If it would be sold on the internet, the payment would be by transfer like with Paypal or by credit card. If the product is sold in a store, the rules of the store had to be followed.

To produce the prototype of The GreenHouse budget of 150.00 € was given. For that reason, a selling price around 200.00 € seemed fair with that. At the beginning, the company could be selling a certain number of units with a lower price to promote the product and then starting with the standard price in order to make profit and stablish its gap in the market.

Occasionally, the company could make promotions or discounts at strategic times such as Christmas surroundings or at the beginning of the scholar year to improve the sales.

4.7.3 Promotion

Promotion includes all the actions taken to make the product known and encourage the consumer to buy it. There are several means of communication such as advertising, sales promotion, public relations, internet advertisements, print media… For The GreenHouse, a leaflet had to be designed to introduce it to the potential customers. This leaflet could be distributed directly on the street or it could be sent by traders or by ordinary post according to market studies.

Figures 25 , 26 , 27 , 28 show the leaflet.

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

<WRAP centeralign>

</WRAP>

Social networks will also be used to share the product, especially the most used ones. A Facebook and Instagram profile pages were made to promote the product, update videos and pictures from users and all kinds of tutorials to help in the usage of the product. At the same time, a Twitter profile was opened, so the customers were allowed to interact with the company asking questions or tagging pictures with the product. Another promotion measure that is working really good nowadays is giving the product to some “influencers” of the moment and letting them interact and talk about the product in online videos. All these measures were fairly affordable in terms of budget, and especially with the influencers, the impact is really big because thousands of people will watch the videos. The focus had to be on the correct target to not lose resources and time. With the aim of promotion, the company has 5000.00 € of budget. The information and the details of how it was be spent can be found in chapter 4.8 Budget.

4.7.4 Place